As a full-service firm made up of architects, engineers, and interior designers—plus support staff—TSP, Inc. gets the job done through collaboration.

Since architect Harold Spitznagel founded the firm in 1930, it has relied on cutting-edge tools to design the legacy buildings that can be found around the Upper Midwest and beyond. Its decades-long history of a network of offices—currently located in Sioux Falls, Rapid City, Watertown, Rochester, MN, and Omaha, NE—has meant an eager willingness to embrace all that technology has to offer.

TSP’s lengthy experience in long-distance collaboration is proving invaluable as changes in the business world occur daily during the global pandemic of the COVID-19 virus. CEO Jared Nesje and an executive team quickly decided to give team members in every office the option to work from home, and many have chosen to do so. Those who do come into work are closely following the recommended health guidelines.

TSP’s lengthy experience in long-distance collaboration is proving invaluable as changes in the business world occur daily during the global pandemic of the COVID-19 virus. CEO Jared Nesje and an executive team quickly decided to give team members in every office the option to work from home, and many have chosen to do so. Those who do come into work are closely following the recommended health guidelines.

Whenever possible, onsite client meetings have been shifted to virtual meetings, said Kari Kiesow, HR director.

“This was an easy decision as our team members safety is the firm’s No. 1 priority,” she said. “We take the recommendations from our local and state leaders seriously and want to do the best for our community. We are confident that with the technology we already have in place we can still provide the same great service to our clients, just from a different seat.”

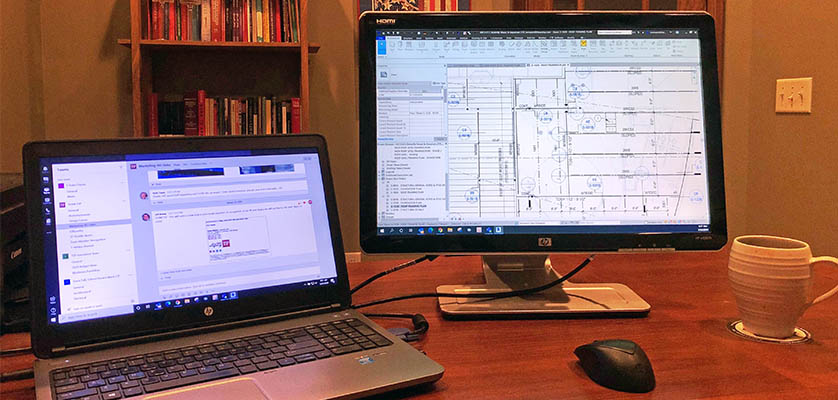

So, while laptop computers now may sit in home offices or on kitchen tables in Minnesota, Nebraska, and South Dakota, they are not idle as team members adjust to a temporary new normal. Communication throughout the day often takes place on Microsoft Teams, which offers chat, video, and voice tools for meetings and daily opportunities to share. TSP’s virtual private network, or VPN, allows team members to send and receive data across shared networks as though their computers were connected directly to TSP’s private network, with all the security needed.

More than ever, coworkers are using technology to remain productive: sharing files, updates, and computer screens, video-chatting while getting answers to questions. A temporary take-over of a coworker’s screen makes sure there is no confusion as to the subject matter. One technology that allows the message to be shared is commonly known as a QR code, or Quick-Response code.

More than ever, coworkers are using technology to remain productive: sharing files, updates, and computer screens, video-chatting while getting answers to questions. A temporary take-over of a coworker’s screen makes sure there is no confusion as to the subject matter. One technology that allows the message to be shared is commonly known as a QR code, or Quick-Response code.

QR codes are matrix barcodes that have been around for more than 25 years. The barcodes contain data for a particular website or application. At TSP, the QR codes can be sent to clients via email and offer the client a standing panoramic image of their building’s design.

QR codes are matrix barcodes that have been around for more than 25 years. The barcodes contain data for a particular website or application. At TSP, the QR codes can be sent to clients via email and offer the client a standing panoramic image of their building’s design.

“If our clients are able to scan QR codes with their phones, we can generate the codes and they can ‘see’ their building,” said Justin Halse, who divides his time in TSP’s Sioux Falls office working as a BIM coordinator and assisting Design Technology Director Jason Nelson. “Or if they have Google cardboard or another Virtual Reality headset that requires you to use a phone, they can scan those through the QR codes and look at them through VR.”

TSP’s Sioux Falls office also has a VR headset which allows the client to walk through a model of their building, giving them the ability to actually “step inside” the virtual structure and walk down the hallways and into the various rooms. Clients who also use Microsoft Teams can share the TSP screen and walk through the model that way, Halse said.

For years, TSP has used building information modeling software such as Revit and Lumion to design building renderings for clients to view. The clash-detection software Naviswork allows engineers to determine any issues with structural, mechanical, and engineering designs long before the buildings come together.

For years, TSP has used building information modeling software such as Revit and Lumion to design building renderings for clients to view. The clash-detection software Naviswork allows engineers to determine any issues with structural, mechanical, and engineering designs long before the buildings come together.

Another design software, Enscape, allows designers to turn out renderings in a matter of minutes, Halse said. Clients who want to see different colors of bricks, for example, easily can see the different options.

TSP also has 3D printers in its Sioux Falls and Rapid City TSP offices, giving clients in any of their office the opportunity to view a realistic model of their structures. They can be sent out to any client in any location, although Halse cautions they take time for the printer to assemble.

“At the end of the day, we want the same thing as our clients, and that is to design and build things better and faster,” Nelson said. “Any technology we evaluate goes through that same scrutiny. If it can make TSP, our designs, our employees, and our clients’ projects and experience better and faster, we want to see how we can make it fit for us.”